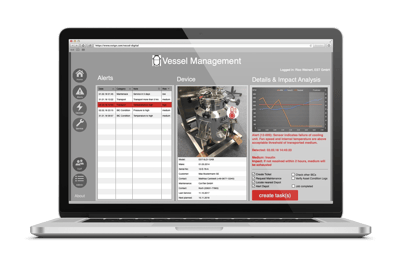

Accompanying process containers from the pharmaceutical, cosmetics and chemical industries on their logistical path with the aid of a web-based application creates maximum transparency and quality assurance throughout the entire process chain. Intelligent sensors enable communication and interaction within the IoT ecosystem.

Process vessel manufacturers, users and their customers are faced with the following difficulties:

Process vessel manufacturers, users and their customers are faced with the following difficulties:

- They have only a limited level of information about the location of the containers, because geocoding is hardly used.

- In addition, it is very difficult to monitor the condition of the transported goods. Access to the data is only possible via central systems.

- Load change cycles are currently still calculated manually and limit value overruns are insufficiently detected and reported